We are a traditional metal components manufacturer of the electronic and automotive industries with close to 50 years experience. Thanks to our extensive technological competences, we are able to competitively manufacture metal components for battery parts.

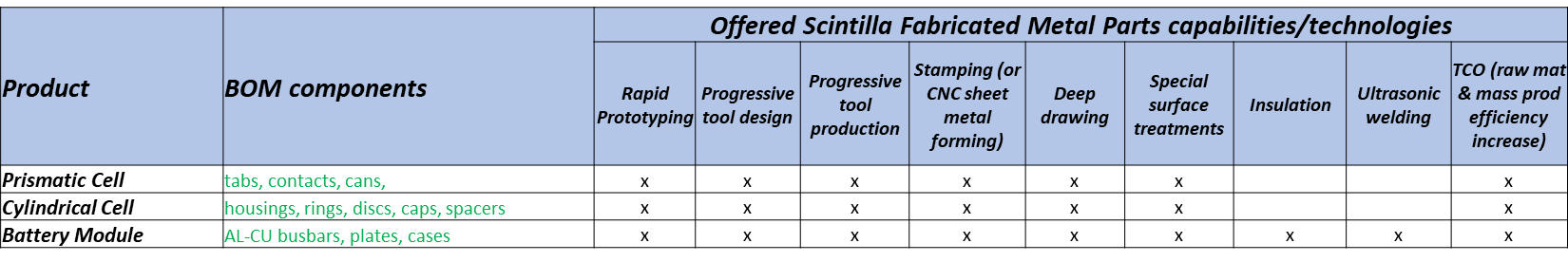

We are ready to produce You the below battery parts (BOM components):

metal TABS, CONTACTS, CANS, CASES, RINGS, DISCS, CAPS, SPACERS, AL-CU BUSBARS, PLATES, HOUSINGS

with the marked (x) in-house technical competences:

STAMPING & BUSBARS

We are traditional stamping metal components manufacturer of the electronic and automotive industry.

STAMPING:

– In-house metal tool design and production

– Significant stamping tool transfer experience (10-50 tools/year, overall 500+ tools transferred)

– Reverse engineering knowledge

– Rapid prototyping capability

– 1+ billion stamping capacity per year

– 40+ years experience, GE & Tungsram heritage

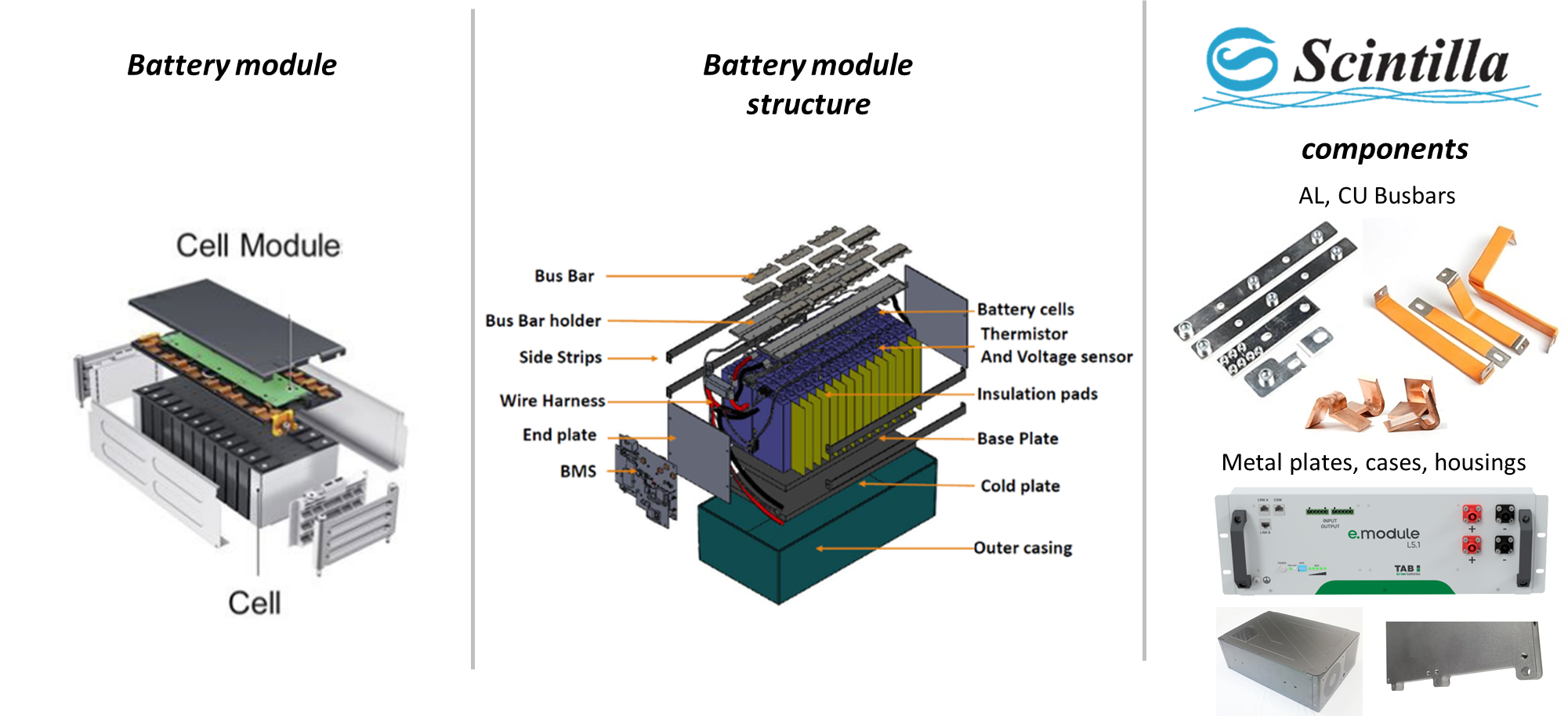

We are one of the first and biggest busbar manufacturer/specialist regarding environmental-friendly (EV, BEV, HEV, PHEV) vehicles in the CEE region.

BUSBARS – the current & future high-runners of our stamping portfolio:

– Rapid busbar prototyping

– In-house washing and nickel plating

– Semi-automatic, robotized busbar production line

– Ultrasonic welding capability

– 20+ million busbars produced per year (100+ million produced overall)

– 5+ years dedicated busbar production experience

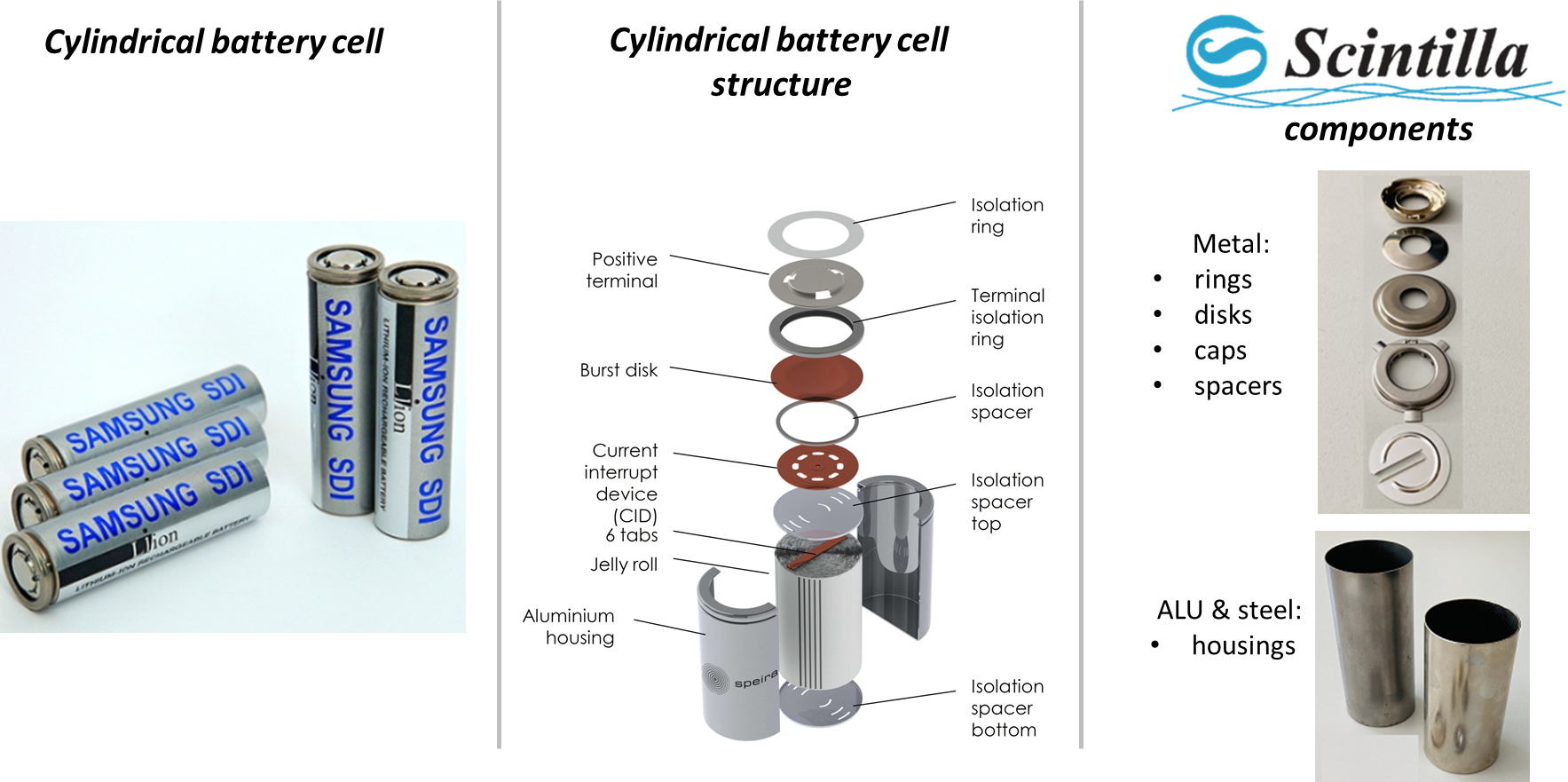

Scintilla components for cylindrical battery cell series

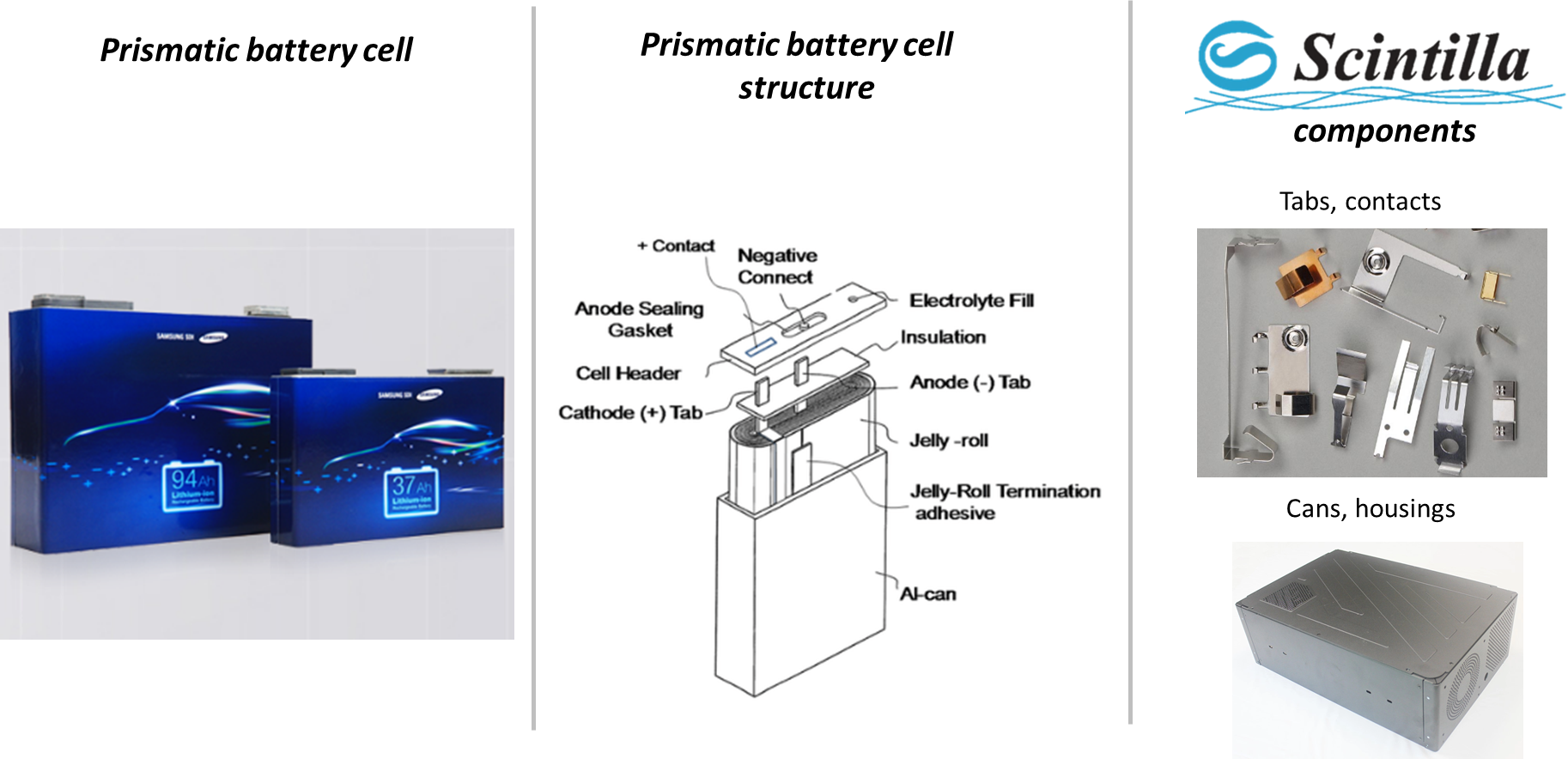

Scintilla components for prismatic battery cell series